Valmar Snowy TTi Range

Featuring the cutting-edge Valmar TTi combisystem, the Snowy TTi horizontal batch freezer is the Valmar flagship model and the creme de la creme of horizontal batch freezers.

Valmar Snowy TTi batch freezers allow you to process small and large quantities of gelato, with production flexibility and speed. The specially designed blade and high-performance scrapers spread gelato on the whole cylinder surface thus avoiding the excessive freezing of gelato on the blades or in the middle of the cylinder.

- 4.3″ LCD Touchscreen featuring 16 preset programmes

- 5 free programmes to save your favourite processes

- Range of sizes – up to 27kg per batch

- The Valmar ECS system allows full accessibility through Wifi for downloading and uploading key information.

Established in 1987, Valmar Global is an innovative manufacturer of specialised machines for ice cream production, confectionery, food service and Ho.Re.Ca. Based in Volcja Draga, Slovenia, Valmar is known worldwide for seamlessly integrating cutting edge technology with reliability in all their machines. We are proud to be the UK distributor of Valmar products since 2008.

Valmar Combisystem

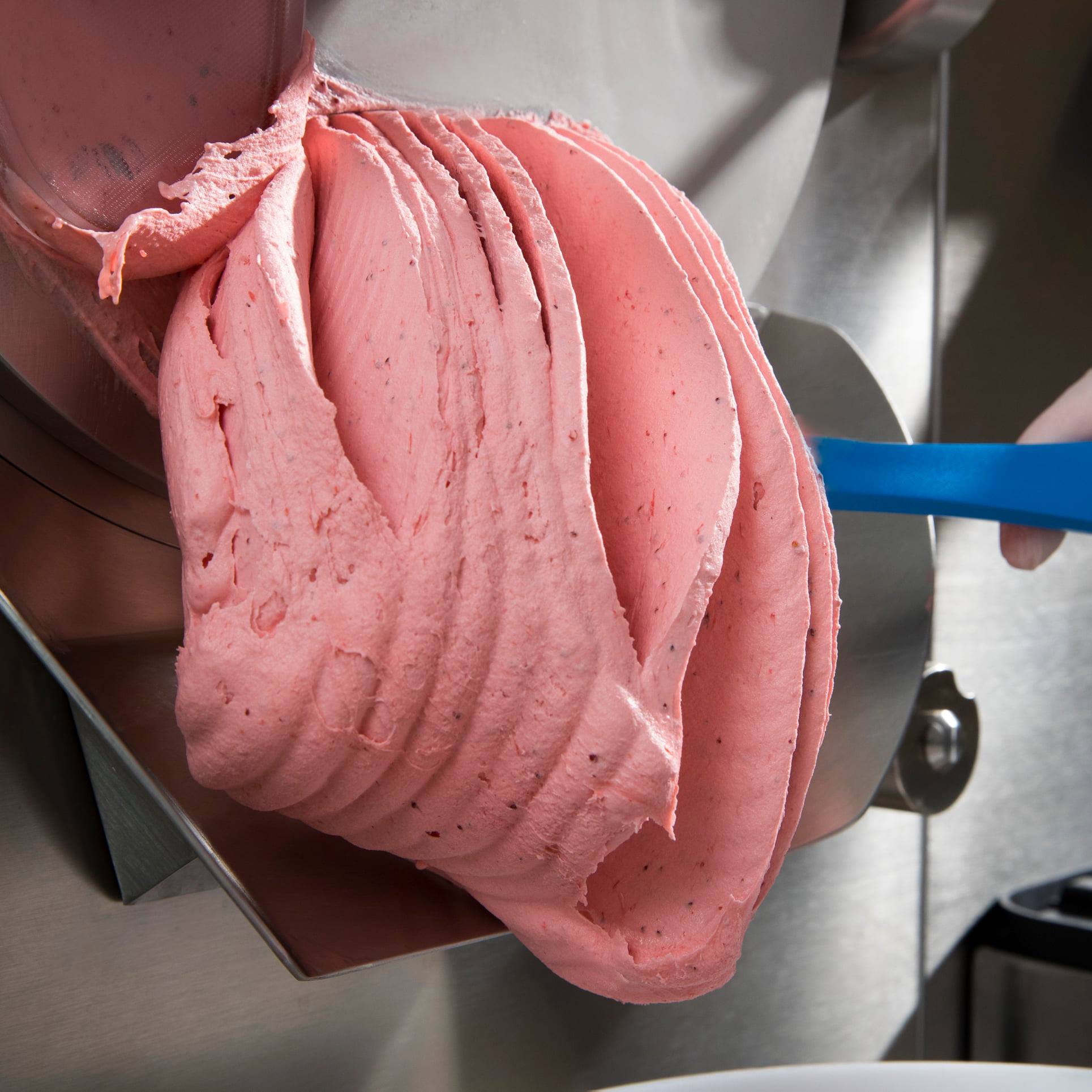

The cutting-edge Valmar COMBISYSTEM is the unique and innovative batch freezing system patented by Valmar and installed in all the batch freezers of the TTi series. The system automatically adjusts to your process demands, selecting the optimal batch freezing method based on the recipe, workflow, and production rate. As a result the processed gelato does not melt quickly and is perfectly creamy, soft and easy to be worked with a spatula, even at core temperatures of -12°C. Standard overrun up to 40% of mix weight.

Start & Stop Extraction Mode

The “Start&Stop” extraction mode, onboard all Valmar TTi batch freezers, allows you to decrease and increase the beater speed just pressing a key, thus interrupting and resuming the gelato flow.

This way you’ll have all the time you need to garnish the pan you are creating: no need to keep opening and closing the ejection gate when making variegato! And the product structure will stay just perfect from the first pan to the last.

Options to suit your business

| Model | Max Hourly I/C Production | Max Vol Per Batch (Liquid Mix) | Min Vol Per Batch (Liquid Mix) | Dimensions | Power Usage |

|---|---|---|---|---|---|

| Snowy 5 TTi | 45 L | 5 Kg | 1.5 Kg | W521xD721+241xH1454 mm | 16 A – 7 Kw – V400/50/3 |

| Snowy 5 TTi 1PH | 42 L | 5.5 Kg | 1.5 Kg | W521xD721+241xH1454 mm | 32 A – 6 Kw – V230/50/1 |

| Snowy 7 TTi | 60 L | 7.5 Kg | 1.5 Kg | W521xD721+241xH1454 mm | 16 A – 7.6 Kw – V400/50/3 |

| Snowy 12 TTi | 100 L | 12.5 Kg | 2 Kg | W521xD721+242xH1454 mm | 20 A – 10.9 Kw – V400/50/3 |

| Snowy 16 TTi | 130 L | 15.5 Kg | 3 Kg | W611xD839+241xH1454 mm | 25 A – 15.3 Kw – V400/50/3 |

| Snowy 18 TTi | 150 L | 18 Kg | 3 Kg | W611xD839+241xH1454 mm | 25 A – 16.2 Kw – V400/50/3 |

| Snowy 27 TTi | 220 L | 27 Kg | 4 Kg | W611xD925+241xH1454 mm | 32 A – 21 Kw – V400/50/3 |